Global Manufacturing Support Led by Proven Operators and Disciplined Processes

Through long-standing relationships with vetted manufacturing partners worldwide, we support a wide range of apparel manufacturing needs with direct oversight and accountability at every stage.

Our role is to simplify production, reduce risk, and provide clients with a reliable, well-managed path from development to delivery.

BENEFITS OF OUR SERVICES

Access to duty-free and preferential manufacturing programs for key global markets

A dedicated production and account manager

Ongoing production and merchandising follow-up

A single point of contact for clear and efficient communication

Product development and design support

Access to a network of certified, compliant factories globally

Factory Evaluation & Product Negotiation

Support for social compliance auditing

Factory-level quality control and inspection oversight

Elimination of costly buyer travel and on-site management expenses

OUR GLOBAL MATERIAL NETWORK

We believe strong manufacturing outcomes are built through collaboration and long-term partnerships.

Over the years, we have developed a global network of trusted yarn producers, knitting mills, dyeing and printing facilities, and material and chemical suppliers. This network allows us to support a wide range of performance, aesthetic, and sustainability requirements across apparel and technical products.

Beyond traditional manufacturing partners, we work within established supplier ecosystems that drive material innovation and performance advancement. This includes access to advanced fibers, coatings, finishes, and textile technologies used across global markets.

By maintaining close relationships throughout the supply chain, we help clients identify and utilize innovative materials efficiently, responsibly, and at the right stage of product development.

Our role is not to overpromise novelty, but to provide practical access to proven and emerging textile solutions that align with product requirements, compliance standards, and market expectations.

ACCREDITED QUALITY TESTING LABORATORY FACILITIES

DEVELOPMENT & DESIGN

Design and Prototyping Support

Many brands rely on our development and design support to move concepts from idea to production-ready products with clarity and confidence.

Our team brings practical knowledge of fabrics, construction methods, and manufacturing processes into the design phase, helping ensure that creative ideas are aligned with production realities from the start.

We work collaboratively with clients throughout development, refining designs, materials, and specifications through structured feedback and iteration. This approach reduces risk, improves efficiency, and shortens the path to production.

Sampling and prototyping are coordinated through trusted development partners and production facilities, allowing clients to evaluate materials, fit, and construction before committing to full-scale manufacturing.

To further support speed and accuracy, we utilize modern development tools, including digital design and 3D CAD workflows where appropriate. These tools help visualize products earlier, streamline revisions, and improve communication across teams.

Our objective is not to overcomplicate design, but to create a clear, efficient development process that supports quality, consistency, and timely execution.

INTEGRATED GLOBAL MANUFACTURING OPERATIONS

We coordinate manufacturing operations across a global network of trusted production partners to support a wide range of apparel and headwear programs, including custom and technical headwear, as well as sportswear, casual wear, formal wear, and outerwear across both knit and woven constructions.

Rather than relying on a single facility or rigid structure, our model emphasizes coordination, oversight, and accountability across each stage of the manufacturing process. From material sourcing and development through production planning and delivery, we work closely with partners to ensure consistency, efficiency, and quality.

This approach allows us to provide end-to-end manufacturing support without unnecessary complexity, helping clients reduce risk, improve execution, and adapt more easily to changing market demands.

Our longevity in the industry is built on long-term relationships with manufacturing partners and clients alike. We value alignment, transparency, and shared objectives, and we seek the same principles in every partnership we maintain and develop.

WORKING BEHIND THE SCENES FOR ESTABLISHED GLOBAL BRANDS

We support brands and suppliers across international markets by coordinating the manufacturing and delivery of premium products for distribution throughout the United States, Europe, Canada, and beyond.

Our role is to operate quietly and effectively behind the scenes, ensuring that production, quality standards, and delivery requirements are met with consistency and care.

Labor welfare standards, quality requirements, and product specifications are addressed through vetted manufacturing partners and monitored throughout the production process. Compliance and accountability are treated as non-negotiable, not optional.

Many of our client relationships are long-term and confidential, reflecting the trust placed in us to execute reliably behind the scenes.

OUR GLOBAL PRESENCE

QUICK FAQ'S &

INFORMATION

Antonio Mac Global Group Inc. has been operating since 1997, supporting brands and businesses through global manufacturing, sourcing, and production coordination.

The group operates as an experienced manufacturing and supply chain partner, helping clients navigate product development, sourcing, and production through trusted global networks. Our focus is on clarity, execution, and reliability, enabling clients to move efficiently from concept to delivery without unnecessary complexity.

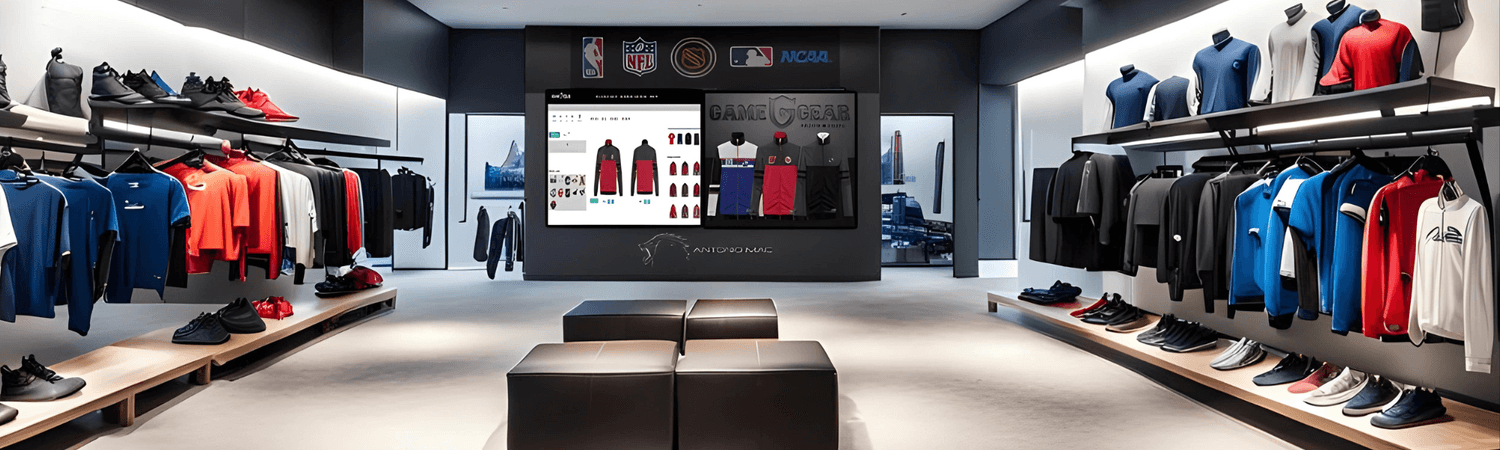

Under the Antonio Mac Global Group Inc. umbrella, we operate and support multiple business divisions and proprietary brands, including Antonio Mac Luxury Couture, Antonio Mac Active Couture, INOvation Lab, and Game Gear, as well as marketing and consulting services aligned with our core operations.

To learn more about our group structure and divisions, visit https://antoniomacglobal.com

Antonio Mac Global Group Inc. operates as a manufacturing and production partner rather than a traditional trading company.

In select cases, we have direct manufacturing involvement through long-standing partnerships, including minority ownership interests with trusted factory partners. In other cases, we work through established joint venture and exclusive production relationships developed and maintained over many years.

Our approach is intentionally relationship-driven. We do not rotate factories for short-term gain. Manufacturing partners are selected carefully, supported consistently, and retained long-term to ensure stability, quality, and alignment for both suppliers and clients.

Many of our production partnerships have been in place for over 2 decades, reflecting our commitment to building durable, mutually beneficial relationships across the supply chain.

Each client is assigned a dedicated account and production manager responsible for overseeing their project from initial briefing through production and delivery.

This role exists to ensure clear communication, accurate execution, and consistent follow-up throughout the manufacturing process. The account manager coordinates directly with production teams and manufacturing partners to monitor progress, address questions, and keep timelines on track.

With decades of experience, we understand that no two clients or projects are the same. Our approach is tailored to fit specific objectives, product requirements, and timelines, rather than applying a one-size-fits-all process.

The designated account manager serves as your primary point of contact and your operational link to the production process, helping eliminate communication gaps and ensuring transparency at every stage.

Quality management is integrated throughout the manufacturing process and coordinated in collaboration with our production partners.

Inspection protocols are applied at multiple stages, including material intake, in-line production, end-line review, and pre-packing checks. Sampling levels are aligned with internationally recognized Accepted Quality Level (AQL) standards, typically ranging from 1.5% to 4%, depending on product type, order requirements, and client specifications.

Fabric and raw materials are inspected prior to production to confirm compliance with agreed standards before being released to the production line. Finished goods are reviewed prior to packing to verify workmanship, measurements, labeling, and packaging accuracy.

In addition to standard quality control procedures, continuous improvement practices are applied across production workflows. Total Quality Management (TQM) principles are incorporated where appropriate to strengthen consistency, accountability, and long-term quality performance.

Our objective is not to promise perfection, but to apply disciplined, repeatable quality processes that reduce risk, support compliance, and deliver products that meet defined specifications and expectations.

Minimum order quantities vary by country of manufacture, product category, and production requirements, including fabric and material minimums.

For larger-scale apparel programs, standard production minimums are typically higher, reflecting the efficiencies and constraints of industrial manufacturing environments. In these cases, minimum order quantities may apply per style and per color, depending on the factory and materials involved.

That said, we recognize that new relationships and phased product launches often require flexibility. Where possible, we work with clients to structure smaller initial runs, split shipments, or multiple styles as part of a longer-term production plan.

Minimums are always discussed transparently and evaluated based on project scope, product type, and long-term alignment. Our objective is not to force volume prematurely, but to establish manufacturing programs that are practical, scalable, and mutually beneficial over time.

Sampling and lead times are structured around each client’s specific product requirements and are confirmed once a Time and Action Plan (TNA) is established.

The sampling process typically progresses through several stages, including concept or prototype samples, fit and size validation samples, pre-production approvals, and production verification samples. Each stage serves a defined purpose and must be approved before moving forward to the next phase.

Timelines are influenced by factors such as material availability, design complexity, testing requirements, and the speed of client feedback. Delays in approvals or changes at any stage may affect subsequent milestones, which is why clear communication and timely collaboration are critical throughout the process.

Bulk production does not begin until all required samples and performance standards are approved. This disciplined approach helps reduce risk, avoid costly errors, and ensure that final production aligns with agreed specifications.

Lead times are always discussed transparently and confirmed on a project-by-project basis. Our role is to manage the process carefully, keep clients informed, and coordinate production efficiently once approvals are in place.

Factory Profiles and Confidentiality

Detailed factory profiles are shared only under confidentiality agreements.

To protect our manufacturing partners and existing client relationships, full factory information is provided following initial discussions and execution of a non-disclosure agreement (NDA).

All potential clients are reviewed prior to engagement. This review process helps ensure alignment, compliance, and the foundation for a productive, long-term working relationship.

For further information, please contact us.